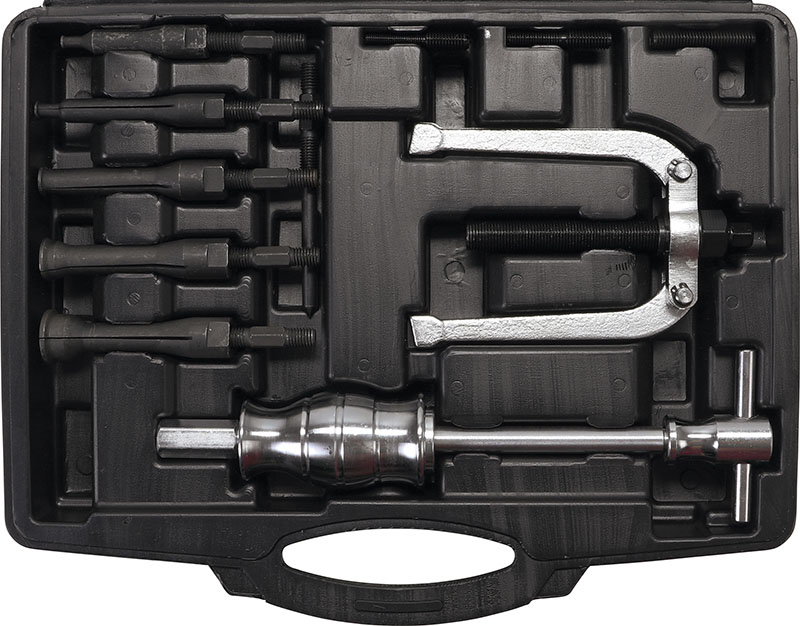

BES-30764 - Strumenti da Meccanico - beselettronica - Kit 16pz estrattore cuscinetti a sfere estrattori inferiori per fori ciechi

Estrattore di Ingranaggi, Vespa Estrattore Cuscinetti Interni a 3 Griffe Estrattore per Cuscinetti Auto per Estrattori per Cuscinetti Interni, per Cuscinetti Interni Reversibili Moto e Auto : Amazon.it: Auto e Moto

TecTake 27 TLG Attrezzi Estrattore Cuscinetti Separatori Boccole Auto Montaggio Installazione : Amazon.it: Fai da te

AERZETIX: Estrattore cuscinetti auto meccanica 2 griffe gambe 100mm mozzo cambio 4"- C54360 : Amazon.it: Auto e Moto

Estrattore di Ingranaggi, Vespa Estrattore Cuscinetti Interni a 3 Griffe Estrattore per Cuscinetti Auto per Estrattori per Cuscinetti Interni, per Cuscinetti Interni Reversibili Moto e Auto : Amazon.it: Auto e Moto

Set 31 pz attrezzi per cuscinetti mozzo ruota auto Estrattore cuscinetto ruote acciaio : Amazon.it: Auto e Moto

BES-30770 - Strumenti da Meccanico - beselettronica - Kit estrattori 3 griffe cuscinetti interni esterni 5pz martello scorrevole